Damage Arresting Composites, Part 1: Building Blocks

Discipline: Structures

Webcast Air Date: October 5, 2016

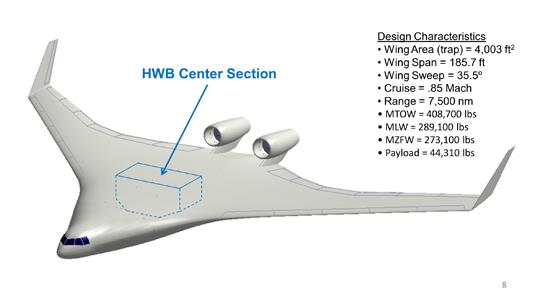

NASA conducted the Environmentally Responsible Aviation Project to explore and document the feasibility, benefits, and technical risk of advanced vehicle configurations and enabling technologies that will reduce the impact of aviation on the environment. A critical aspect of this pursuit is the development of a lighter, more robust airframe that will enable the introduction of unconventional aircraft configurations that have higher lift to drag ratios, reduced drag, and lower community noise. Although such novel configurations like the Hybrid Wing Body (HWB) offer better aerodynamic performance as compared to traditional tube-and-wing aircraft, the blended wing shape with its almost-flat sided pressure vessel poses significant design challenges.

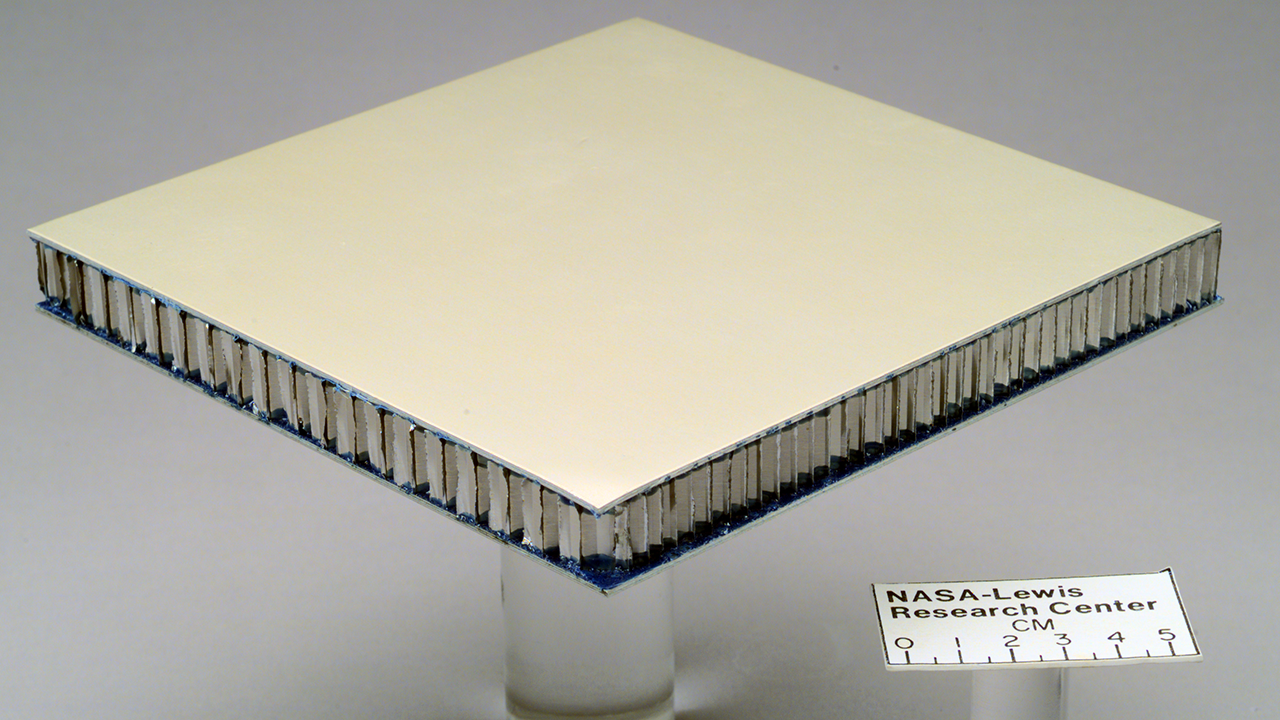

Developing an improved structural concept for a non circular pressurized cabin is the primary obstacle in implementing large lifting body designs. To address this challenge, researchers at NASA and The Boeing Company worked together to advance new structural concepts like the Pultruded Rod Stitched Efficient Unitized Structure (PRSEUS), which is an integrally stiffened panel design that is stitched together and designed to maintain residual load carrying capabilities under a variety of damage scenarios. A building block approach was used in this technology development effort.

This topic will be addressed in two parts. Part one will focus on the structural building blocks from small elements through large panels designed to demonstrate that the concept of out-of-autoclave cured, stitched composite structure with no mechanical fasteners in the acreage of flat and curved panels would efficiently support the axial, bending internal cabin pressure loads representative of the passenger compartment of a HWB vehicle. Part two, to be covered in a separate webcast, will focus on the design, analysis and testing of the complex pressurized structures of a PRSEUS “cube” and a 30-foot-long, 80%-scale, multi-bay box. All building blocks and the built-up structures were analyzed and tested and the results documented to demonstrate the feasibility of the concept for application to commercial transport aircraft.